Desktop Dot Peen Marking Machines are designed and manufactured for marking work pieces made of plastic and metal on the desktop.

Desktop Dot Peen Marking Machines are specially designed for easy marking of small, easy-to-carry workpieces on a bench. In general, the desired workpiece brackets or fixtures are easily mounted on the T slot casting tables of our Desktop Dot Peen Marking Machines. The workpieces can be easily placed on these fixtures, and the marking is easily accomplished by gentle hand pressing. The marking head moves on a z-axis over hardened chrome-plated double spindles by a manual hand wheel or alternatively by a combination of the "Dotpeenator Dot Peen Marking Software" & a programmable z-axis motor for positioning according to the different heights of workpieces up to 42cm*. A Dotpeenator z-axis has metal lids, one with a serigraphic scale to be used as a 'reference' point. The surface of the casting work table is ground and coated with phosphate against corrosion. Dotpeenator Dot Peen Marking Heads are easily fixed on the z-axis at the desired point by a simple manual lock mechanism. Our range of desktop marking machines includes the products with working areas of 90X40MM, 140X40MM, 140X60MM, 170X120MM 205X105MM, 500X400MM. Thanks to the stainless steel dust covers, our dot peen marking machines prevent the linear axes of our machines from getting dusty and have long years of precise and maintenance-free operation. A Dotpeenator desktop dot peen marking machine is configured to work with 3 different dot peen marking technologies. Based on your requirements, we can integrate one model from the pneumatic peen-cartridge quick-marking kit series or, the pneumatic-peen-cartridge high-surface tolerance marking kit series or the electric peen-cartridge marking kit series. Our R&D work is ongoing and we will be adding one more new type of peen-cartridge marking kit soon.

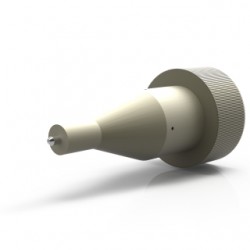

1- 'Electrical Peen-Cartridge Kit'

(Pin Marking / Peening Frequency: 20Hz-50Hz)

2- 'Pneumatic Peen-Cartridge Kit'

a - 'Uneven-Surface Tolerating Kit (Peen Marking / Peening Frequency: 200Hz)

b - 'High-Speed Peen-Cartridge Kit

Our desktop models of dot peen marking machines equipped with either an electrical or a pneumatic peen-cartridge assembly kits are currently used for the following marking operations.

1-Brake Caliper Marking,

2-Brake Adjuster Marking,

3-Piston Marking,

4-Air Bellows Ring Marking,

5-Water Pump Marking,

6-Submersible Pump Marking,

7- Name Plates Marking

8-Axis, Axon Marking,

9-Nut Marking,

10-Mold Marking,

11-Tool Marking,

12-Special Tool Marking,

13-Steel Construction Parts Marking,

14-Steel Profile Marking,

15-Volant Marking,

16-Chassis Marking,

17-Engine, Transmission Body Marking,

18-Spindle Motor Marking,

19-Electric Motor Marking,

20-Resistance Marking,

21-Cam Rod Marking,

22-LPG Tank Marking,

23-Tank Nameplate Marking,

24-Hydraulic Hose Heads Marking,

25-Surgical Tools Marking,

26-Knife Marking,

27-Weapon Marking,

28-Weapon Mechanical Parts Marking,

29-Bomb Body Marking,

30-Gear Marking,

31-Tie-Rot Marking,

32-Ball-Joint Marking

33-Volant Marking,

34-Cast Part Marking,

36-Camshaft Marking

39-Crankshaft Marking

40-Friction Bearing Marking

41-Pulley Marking,

*: Any given value differs based on the requested peen-cartridge assembly kit.