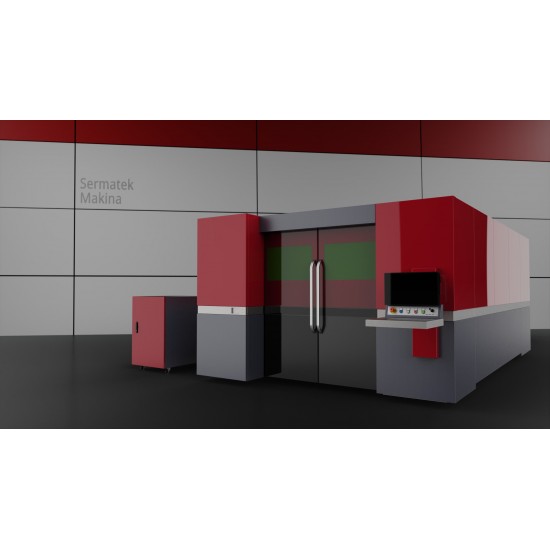

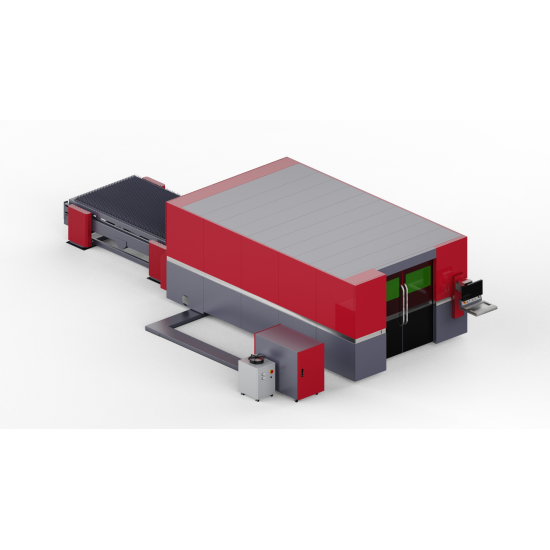

Laserator AGORA 3015 Class-I Fiber Laser Cutting Machine, Laser Cutting, Enclosed Cabinet Laser Cutting System, Laser Cutting Machine

- Model: AGORAFL

Meet the AGORA 3015 closed cabin fiber laser cutting machine from Laserator. This machine, which uses cutting-edge fiber laser technology, is made to deliver unprecedented levels of precision, speed, and dependability.

This machine can effortlessly cut a wide range of materials thanks to its 20kW maximum laser power. Processing is made simple by integrated CAD/CAM software, and the machine processes complicated designs with exceptional accuracy. A top-notch laser beam drives the AGORA 3015 Fiber Laser Cutting Machine, which produces straight, clear cuts free of warping or staining. This makes it one of the most productive tools on the market today, along with its fast cutting speed. The AGORA 3015 Fiber Laser Cutting Machine has an intuitive user interface that makes it simple to use and keep, making it a great option for businesses of all sizes. It is a cost-effective option for your cutting needs due to its low power consumption and low maintenance needs.

- 1kW to 20kW fiber laser power options

- Models: 3015, 4020, 6030

- Class I (Closed Cabin)

- Solid State Laser (Fiber Laser, more efficient)

- EtherCAT Communication

Technicial Specifications

- Steel construction with a low coefficient of expansion, aerospace aluminum bridge and programmed gas suction design

- 1.5m x 3m or 2m x 4m, 6mx 3m size options

- Electrostatic painted cabinet sheets

- Protection with 1064 nanometer ray filter

- 2, 3, 4, 6, 8, 10, 12, 14, 16, 18, or 20kW fiber laser power options

- Control unit with EtherCAT BUS

- Oxygen, nitrogen or compressed air selection and control system

- Water cooling system (Chiller)

- 1G acceleration

- Servo motors and encoders with precision, direct coupling and precision planetary gear group in X, Y, Z and R axes. Maximum free traverse speed of 100m/s

- Automatic sheet loading system

- Light warnings

- Fire resistant axis protection bellows

- LED interior lighting

- Linear slides and ground rack-pinion gear group

- 0.02mm positioning and 0.03mm repeatability accuracy

- Nozzle cooling

- Automatic gas pressure correction

- Automatic nozzle cleaning and calibration

- Double row dust cleaning

- Servo motor speed and torque tracking graph

- Laser power output correction

- Camera follow up

- Automatic sheet edge detection

- Delay settings

- Dust removal in X and Y axis

- "Stop", "Backward", "Auto-backward" commands during operation

- Operation log file

- Ability to set optional limit

- Real-time round cutting tracking

- Custom button and alarm identification

- Manual cut

- Automatic lubrication

- Ability to set speed limit for small circle and arc

- Cooling points

- Power curve